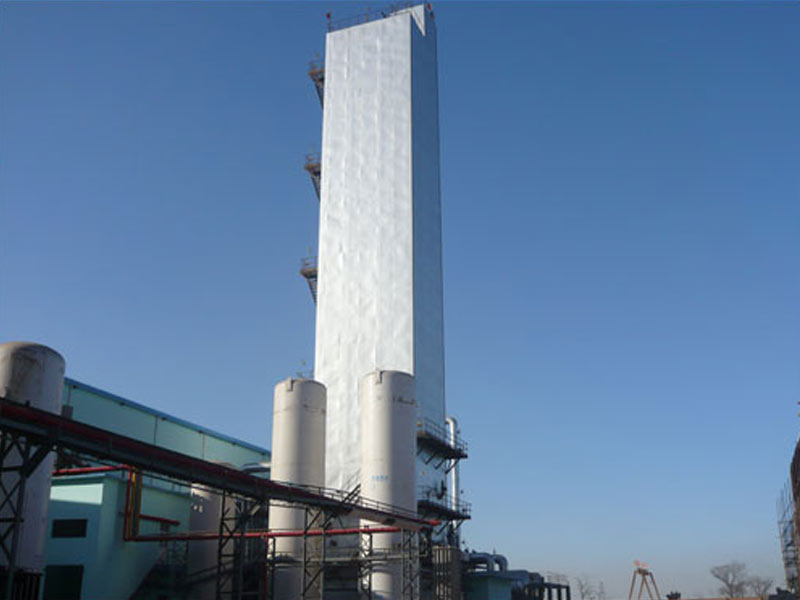

Technology Introduction

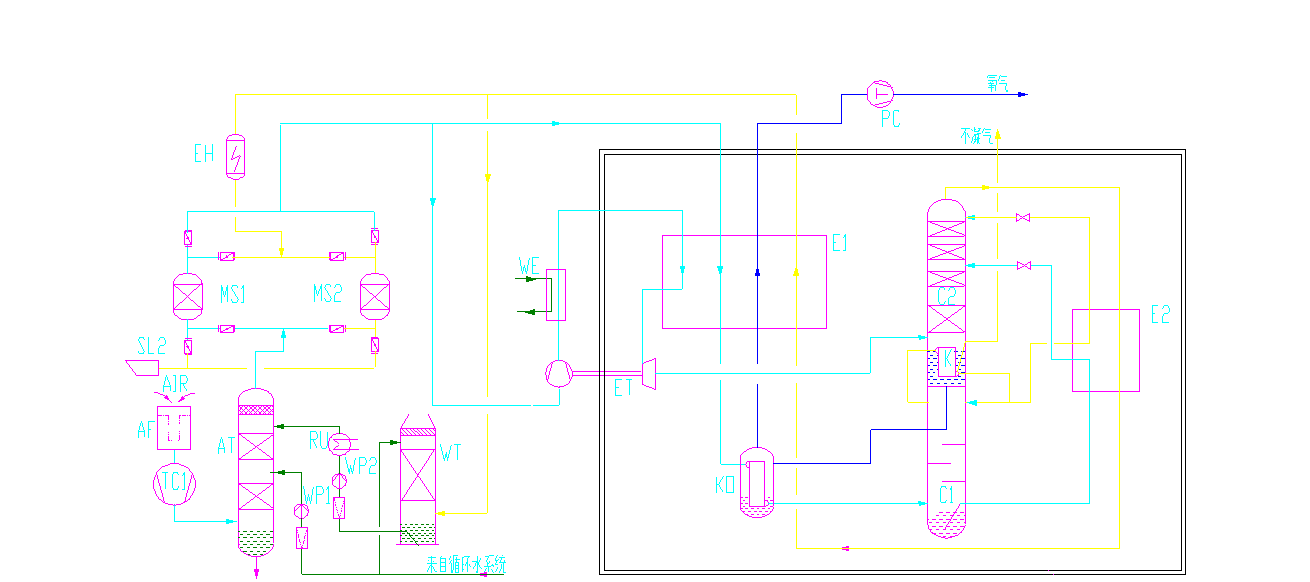

The ASP generates oxygen and nitrogen by cryogenics and is comprised of high-efficiency centrifugal compressor, molecular sieve purification, turbo expander for refrigeration and energy-saving rectification equipments. The control for the device is completed by DCS, and the particular patented technology owned by DEAR Air Separation Industrial Co. is adopted in the technological process which follows the most advanced and general international conventions and carries out the design mode to stable running premise.

Technical feature

1. Simple technological process, simple and stable operation;

2. Stable oxygen purity, little interference factors, long continuous running cycle;

3. Lower power consumption, fewer investments;

4. Oxygen fractionated from fractionating tower with pressure >50 KPa, no extra use of oxygen compressor;

5. High automaticity, easy start and stop;

6. Low running pressure, high safety;

7. Low cost of running and maintenance;

Application Area

Metallurgy, Chemical, Oxygen enriched combustion (industrial boiler, glass furnace, and electrolytic aluminum), Chemical gas producing (synthesis ammonia, methyl alcohol, ethylene, and ethanediol), medical area and sewage disposal (oxygen enriched aeration), paper pulp bleaching, fire-proofing device etc.

Remarks

We can offer energy-saving oxygenerator plan solely according to clients' requirements.

Application of oxygen

In commerce, liquid oxygen is classified as an industrial gas and is widely used for industrial and medical purposes. Liquid oxygen is obtained from the oxygen found naturally in air by fractional distillation in a cryogenic air separation plant.

Liquid oxygen is a common cryogenic liquid oxidizer propellant for spacecraft rocket applications, usually in combination with liquid hydrogen, kerosene or methane. Liquid oxygen is useful in this role because it creates a high specific impulse.[citation needed] It was used in the very first rocket applications like the V2 missile (under the name A-Stoff and Sauerstoff) and Redstone, R-7 Semyorka, Atlas boosters, and the ascent stages of the Apollo Saturn rockets. Liquid oxygen was also used in some early ICBMs, although more modern ICBMs do not use liquid oxygen because its cryogenic properties and need for regular replenishment to replace boiloff make it harder to maintain and launch quickly. Many modern rockets use liquid oxygen, including the main engines on the now-retired Space Shuttle.

Liquid oxygen also had extensive use in making oxyliquit explosives, but is rarely used now due to a high rate of accidents.

It is also used in the activated sludge processing in waste water treatment to maintain a high level of micro-organisms